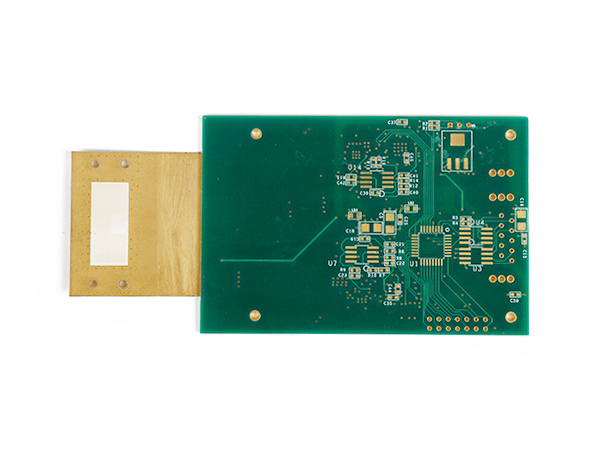

DPC ceramic substrate: high-power lighting, automotive lighting, UVC disinfection, IC circuit board

MATERIAL DATA SHEET,96 Al₂O₃ ceramic

Item | Item | Value | Unit |

Colour Status | Colour | White | — |

Volume Density | Density | >3.7 | g/cm³ |

Thermal Conductivity | Thermal Conductivity | >24 | W/(m·K), 20℃ |

Dielectric Constant | Dielectric Constant | 9-10 | (1MHz) |

Dielectric Loss | Dielectric Loss | 3×10⁻⁴ | — |

Dielectric Strength | Dielectric Strength | >17 | kV/mm |

Flexural Strength | Flexural Strength | >350 | MPa |

Camber | Camber | <3‰ | Length % |

Water Absorption | Water Absorption | — | % |

Volume Resistivity | Volume Resistivity | >10¹⁴ | Ω·cm, 20℃ |

Thermal Expansion Coefficient | Thermal Expansion Coefficient | 20-300℃: 6.5-7.5 300-800℃: 6.5-8.0 | ×10⁻⁶/K |

Aluminum Nitride (AlN) Ceramic Material Properties

Property Value Unit Notes

Color Gray — Visual identification of material

Volume Density ≥ 3.333 g/cm³ High density indicates low porosity and enhanced mechanical/thermal performance

Thermal Conductivity ≥ 170 W/(m·K), 20℃ Excellent thermal management for power electronics, LEDs, and semiconductors

Dielectric Constant 8–10 (1 MHz) Stable at high frequencies, suitable for 5G/microwave components

Dielectric Loss 3 × 10⁻⁴ — Ultra-low energy loss, ideal for high-voltage insulation

Dielectric Strength > 17 kV/mm High voltage resistance for power modules and electrical insulation

Flexural Strength > 450 MPa High structural reliability despite ceramic brittleness

Camber (Flatness) < 3‰ Length % Critical for semiconductor packaging and precision components

Water Absorption Negligible % Zero porosity ensures chemical stability and moisture resistance

Volume Resistivity > 10⁸ Ω·cm, 20℃ Near-perfect electrical insulation for high-power applications

Thermal Expansion Coefficient 2–3 × 10⁻⁶/K (20–300℃) ×10⁻⁶/K Matches silicon/GaN semiconductors for thermal cycling reliability

Key Features Summary

Performance Category Advantages

Thermal High thermal conductivity (170 W/m·K) + low CTE (2–3 × 10⁻⁶/K)

Electrical Ultra-low dielectric loss (3 × 10⁻⁴) + high resistivity (>10⁸ Ω·cm)

Mechanical High flexural strength (450 MPa) + minimal camber (<3‰)

Stability Zero water absorption + chemical inertness

Typical Applications

Electronic Packaging

IGBT/SiC/GaN power modules

LED heat dissipation substrates

MEMS device carriers

Semiconductor Manufacturing

Wafer chucks for CMP processes

Plasma chamber components (high-temperature corrosion resistance)

High-Temperature Insulation

Aerospace thermal insulation structures

High-temperature sensor substrates

Precision Components

Laser heat sinks (high-power)

Optical platform insulators

Technical Differentiation

Thermal-Electrical Synergy:

Combines metal-like thermal conductivity (170 W/m·K) with ceramic-level insulation (>10⁸ Ω·cm).

Thermal Cycling Reliability:

CTE matches silicon (2.6 × 10⁻⁶/K) and GaN, minimizing stress during operation.

Precision Fabrication:

<3‰ flatness ensures compatibility with semiconductor packaging and photolithography.

Why AlN Ceramic Stands Out

"AlN bridges the gap between traditional ceramics (e.g., Al₂O₃) and metals. Its unique combination of high thermal conductivity, electrical insulation, and dimensional stability makes it indispensable for next-gen electronics—from 5G base stations to EV power modules."

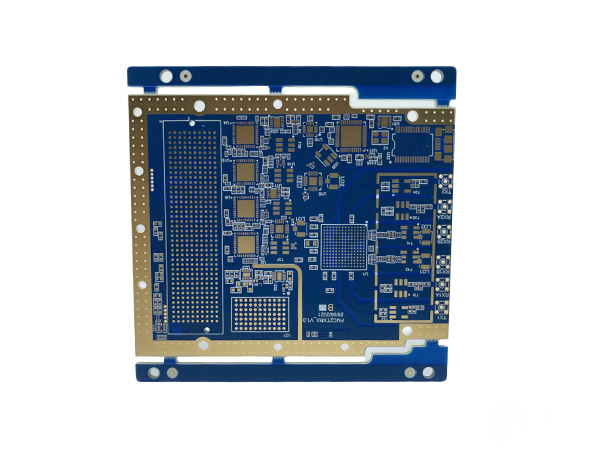

High Frequency PCBs are specialized printed circuit boards designed to handle and transmit high-frequency signals, typically operating above 1 GHz, with some applications extending into the millimeter-wave band (30 GHz and beyond). These boards are engineered to maintain signal integrity and reliability during high-speed data transmission, making them indispensable in modern high-speed communication and electronic syste

High Frequency PCBs are specialized printed circuit boards designed to handle and transmit high-frequency signals, typically operating above 1 GHz, with some applications extending into the millimeter-wave band (30 GHz and beyond). These boards are engineered to maintain signal integrity and reliability during high-speed data transmission, making them indispensable in modern high-speed communication and electronic systems.

Product name: High frequency PCB

Material: Roger RO4350B + Shengyi S1000 FR4

Layers: 4layers

Copper: 1oz

Thickness: 1.20mm

Surface finishing: Immersion Gold 2U"

Soldermask: Taiyo Green soldermask

Application: communication device

Reach out to us via chat, phone, or our simple contact form.

Get a FREE Quote Today

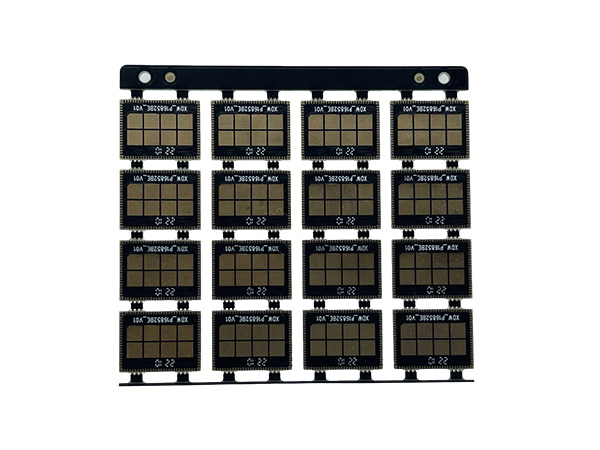

Our business scope includes IC substrate design and simulation, IC substrate manufacturing, IC packaging and testing, as well as comprehensive hardware assembly services(PCB & PCBA).